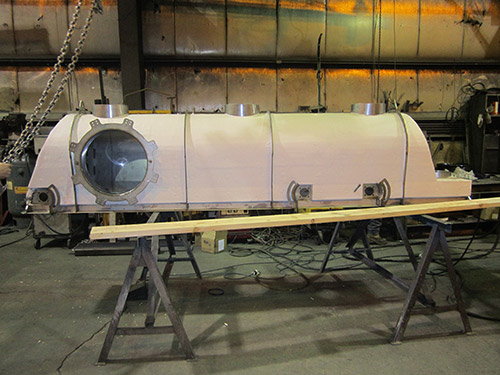

CUSTOM FABRICATION OF A STAINLESS STEEL FLUIDIZED BED COOLER FOR THE CHEMICAL INDUSTRY

As a full-service fabrication shop, no job is too big or small for Harmony Metal Fabrication. This fluidized bed cooler project utilized many of our in-house manufacturing capabilities to the fullest, including sawing, shearing, plasma cutting, forming, drilling, and welding. Constructed of 304 stainless steel, the bed cooler was insulated to meet the requirements of the chemical application and manually assembled. When complete, this unit measured 14′ long by 4′ wide with material thickness of 2″, and weighed 4,500 lbs. Working to tolerances of ±1/16″, this custom fabricated stainless steel project met all of our high quality standards as well as exceeding the customer’s expectations.

To learn more about our custom metal forming services, including details on this fluidized bed cooler project, please see the table below or contact us today.

Custom Stainless Steel Fabrication Project Highlights

| Product Name | Fluidized Bed Cooler |

| Product Description | This fluidized bed cooler is used within a chemical application. |

| Capabilities Applied/Processes | Cutting

Fabrication

Insulating-High Temp Assembly-Manual |

| Equipment Used to Manufacture Part | Sheer Band Saw Press Brake Plate Roll Drill Press Welder |

| Overall Part Dimensions | Material Thickness: 2" Length: 14' Witdh: 4' |

| Tightest Tolerances | ±1/16" |

| Material Used | 304 Stainless Steel |

| Material Finish | Color Clean |

| In Process Testing/Inspection Performed | Final Inspection |

| Estimated Part Weight | 4,500 lbs |

| Industry for Use | Chemical |

| Turnaround Time | 5 Weeks |

| Standards Met | 3D CAD Drawing |