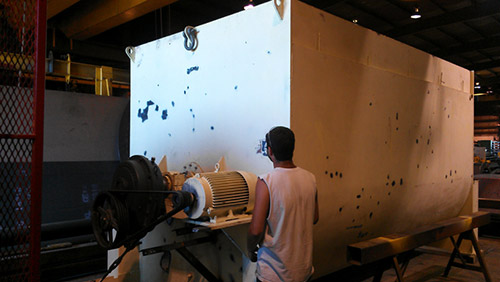

CUSTOM STEEL FABRICATION OF A CHOCOLATE AGITATION / HOLDING TANK FOR THE CHOCOLATE INDUSTRY

Harmony Metal Fabrication is a certified specialist when it comes to custom fabrication for advanced projects. A customer aware of our capabilities contracted us to build a chocolate storage tank in the project discussed here. We were able to provide a complete solution without compromise to quality or performance.

The design of this storage tank was provided by the customer, measuring 16’ long, 8’ wide, and 10’ high. The metal was specified, with thickness ranging from 1/8” to ¾”, and tolerances of ±1/8″.

Our fabrication of this 12,000 lb. carbon steel storage and agitation tank required use of many differing processes. These included burning, shearing, plasma cutting, sawing, sheet forming, rolling, drilling, welding, and punching, followed by assembly and enamel painting. After assembly, we operationally tested the completed tank and inspected it for any fluid leaks.

The chocolate industry customer received a completed agitation and storage tank in only 10 weeks.

Select Harmony Metal for your project, and your production needs will be completed with the same level of quality and service. Contact us today to learn more.

Custom Steel Fabrication Project Highlights

| Product Name | Custom Steel Tank |

| Product Description | This custom steel tank is used for agitation and holding of chocolate. |

| Capabilities Applied/Processes | Cutting

Fabrication

Manual Assembly Painting |

| Equipment Used to Manufacture Part | Sheer Band Saw Press Brake Plate Roll Drill Press Welder CNC Plasma Cutter |

| Overall Part Dimensions | Material Thickness: 1/8” to ¾” Length: 16’ Width: 8’ Height: 10’ |

| Tightest Tolerances | ±1/8” |

| Material Used | Carbon Steel |

| Material Finish | Industrial Enamel Paint |

| In Process Testing/Inspection Performed | Hydrostatic Leak Test Final Inspection |

| Estimated Part Weight | 12,000 lbs. |

| Industry for Use | Chocolate |

| Turnaround Time | 10 Weeks |

| Standards Met | 3D CAD Drawing |